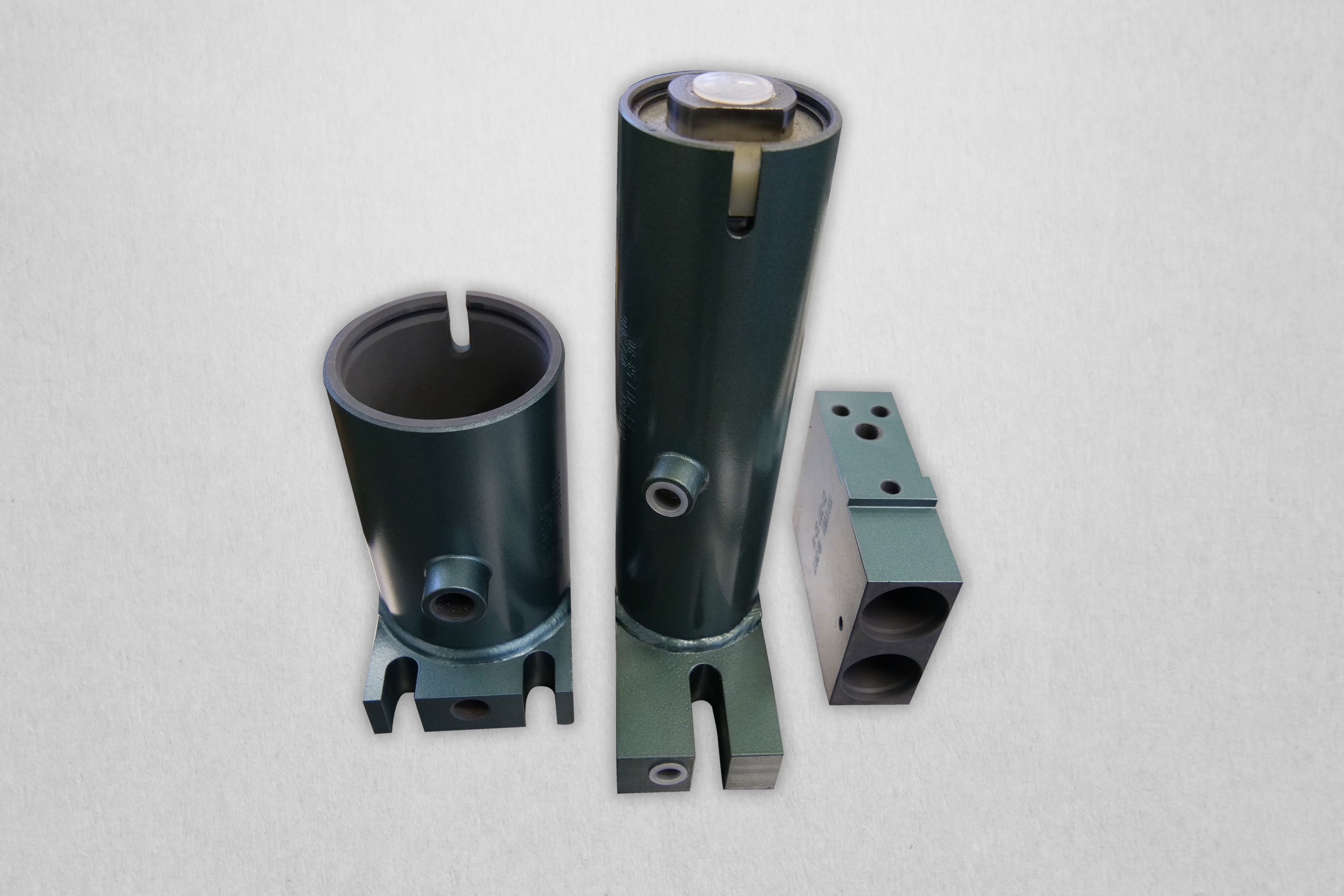

Depending on the field of application, welding cylinders are used in various embodiments, for example in the automotive, wire and sheet metal industry, for welding in corresponding welding devices and tools.

The Offer

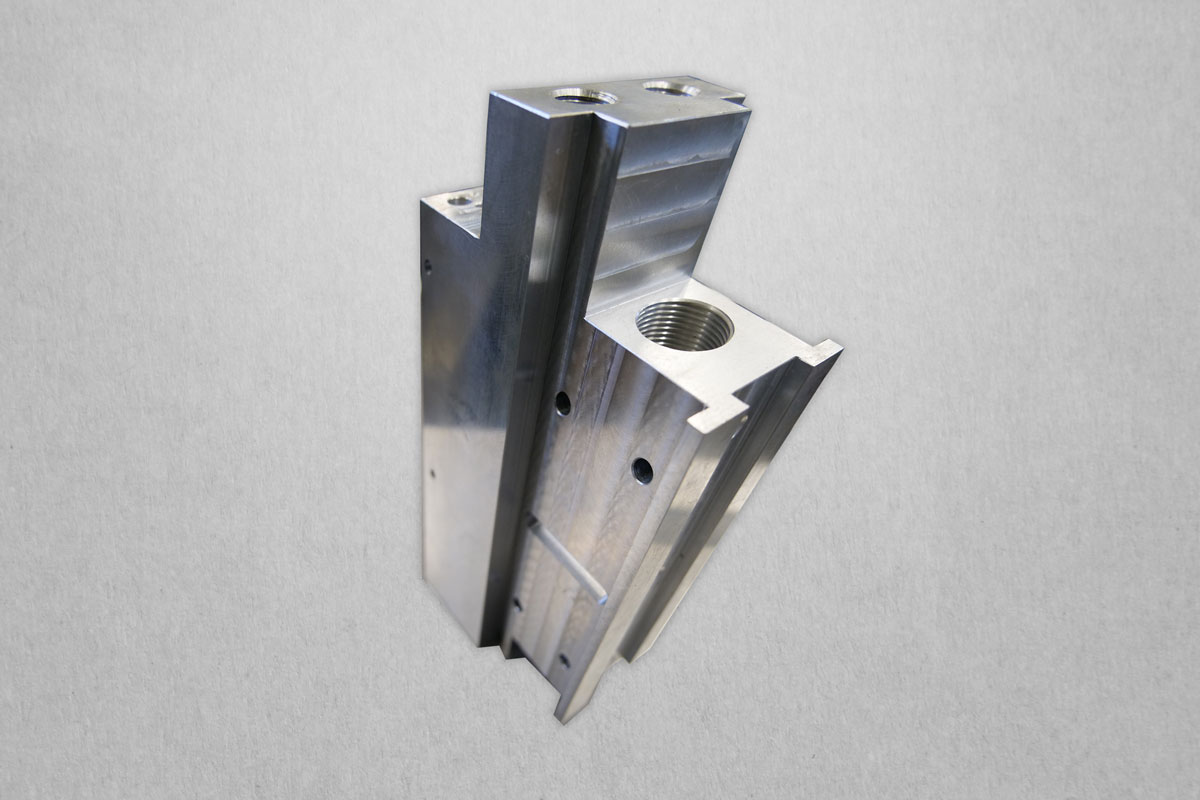

Our cylinder program is the result of decades of experience and continuous cooperation with our customers. It covers both the standard according to DIN and the factory standards of European car manufacturers. A high weighting has the customer-specific problem solution, which offers an optimal cost-benefit ratio at a high quality level. Through our market-driven development, we can access a variety of project solutions that are not included in the standard. If you can’t find the right product for your specific problem in our catalog, we are available for an individual solution. We are happy to help.

The Quality

In terms of quality, we are absolutely uncompromising. For more than three decades, our welding cylinders have demonstrated this in the harsh daily routine of spot welding. High mileages, low maintenance, ease of installation and high reliability are features that positively influence your cost accounting. By consistently exploiting state-of-the-art production technologies, using high-quality materials and tight manufacturing tolerances, we continuously maximize the quality of our products and minimize investment costs for you at a fair price-performance ratio.

Product Overview

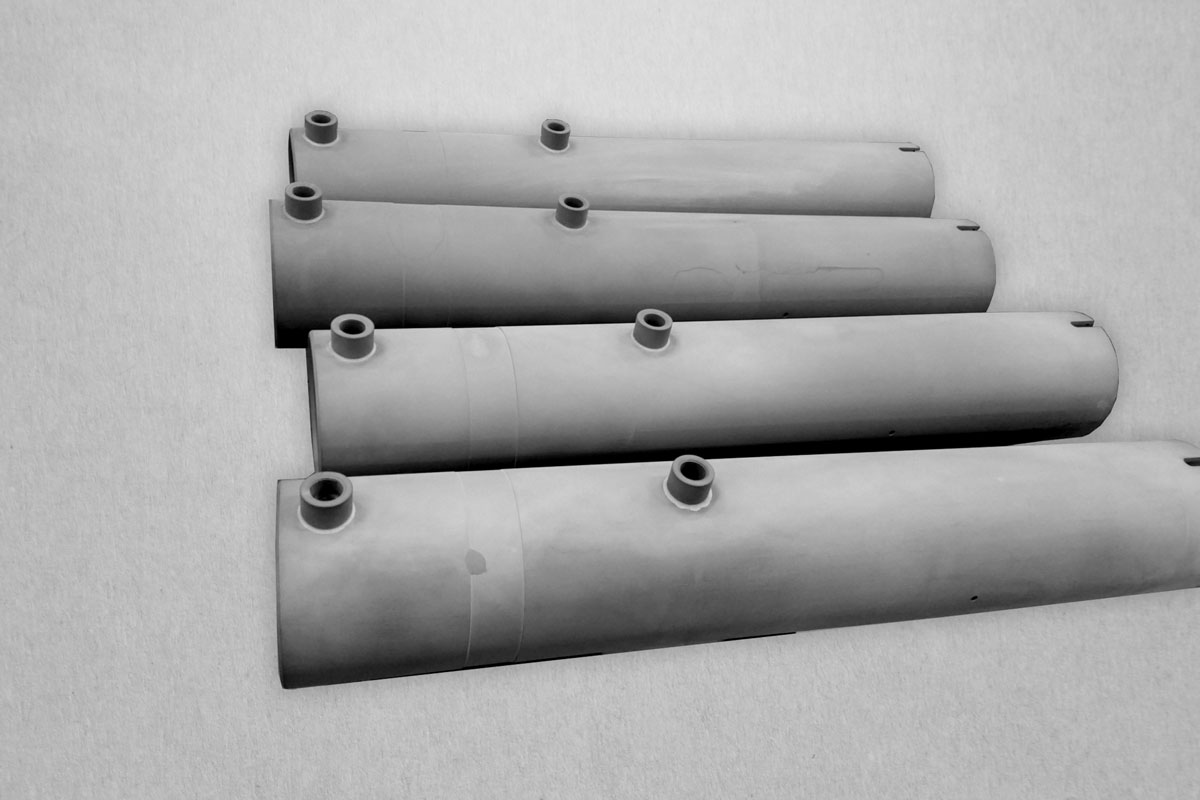

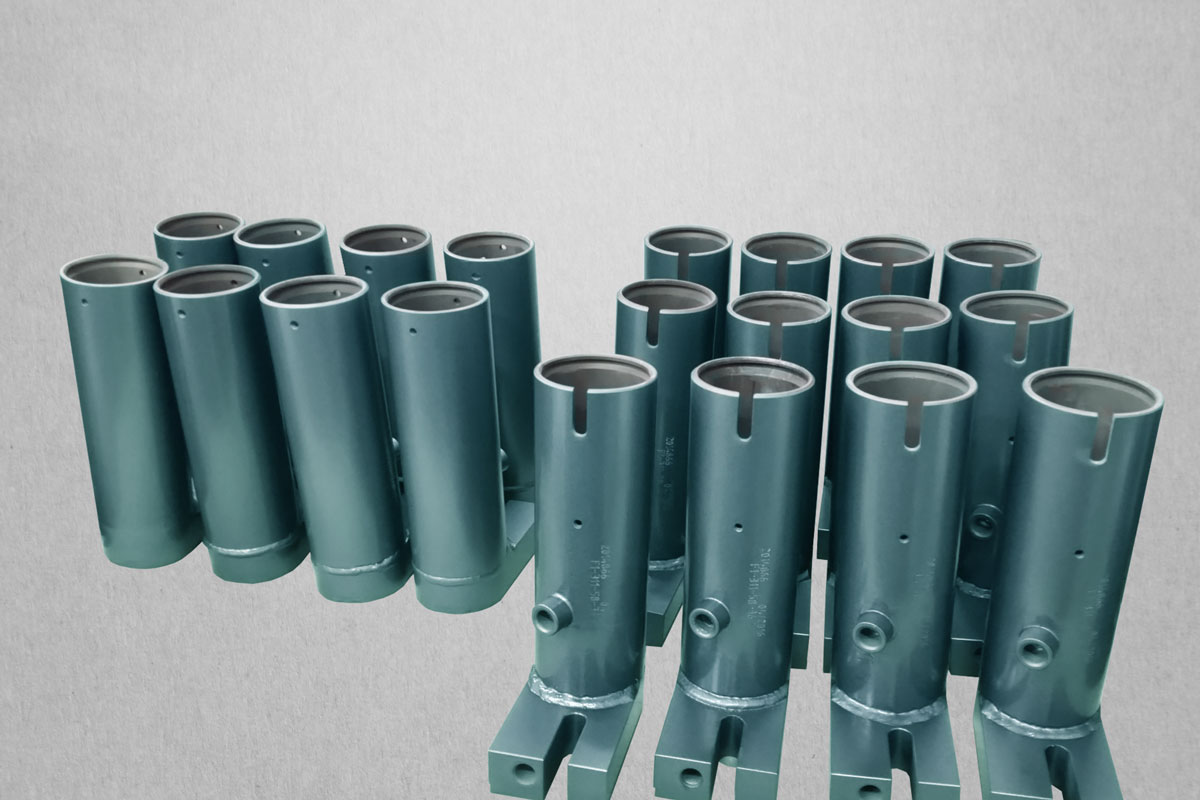

- Multi-stage pneumatic cyl

- Multi-stage pneuma. Duplex and triplex cyl.

- Multi-stage pneuma. Pre and working stroke cylinder

- Welding cylinder. with damping

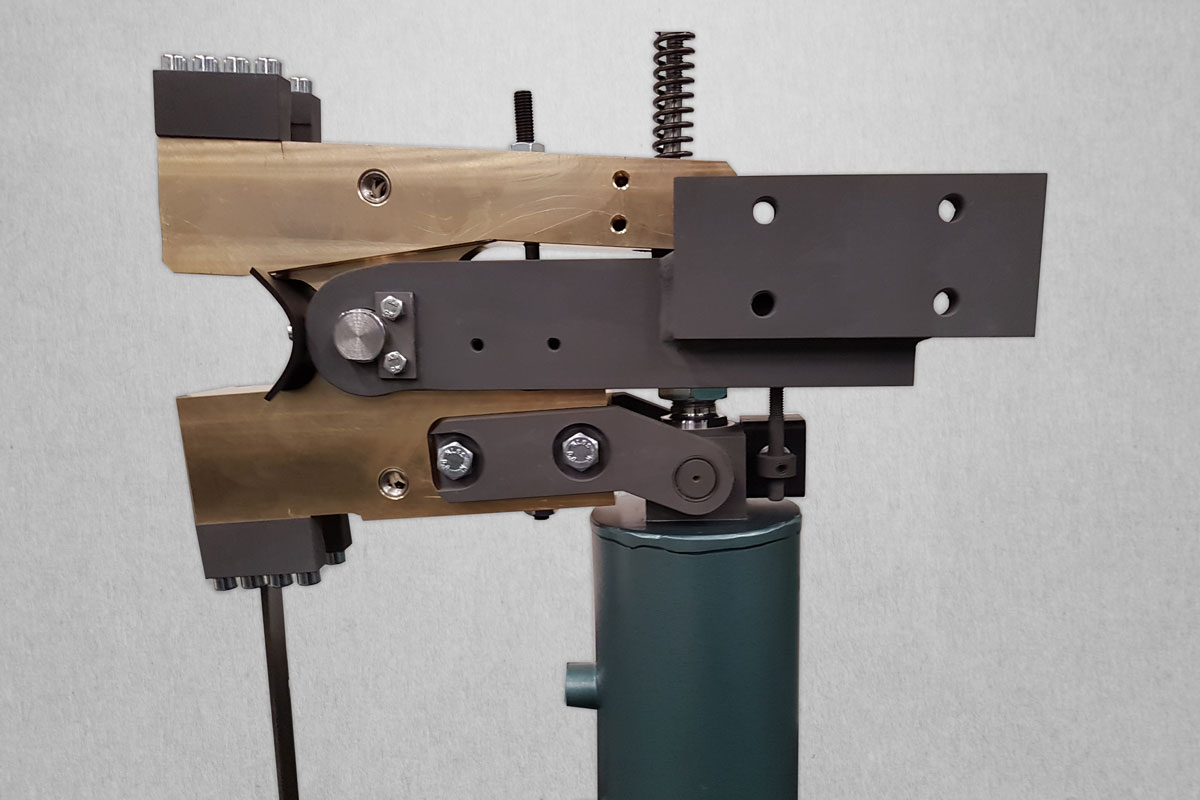

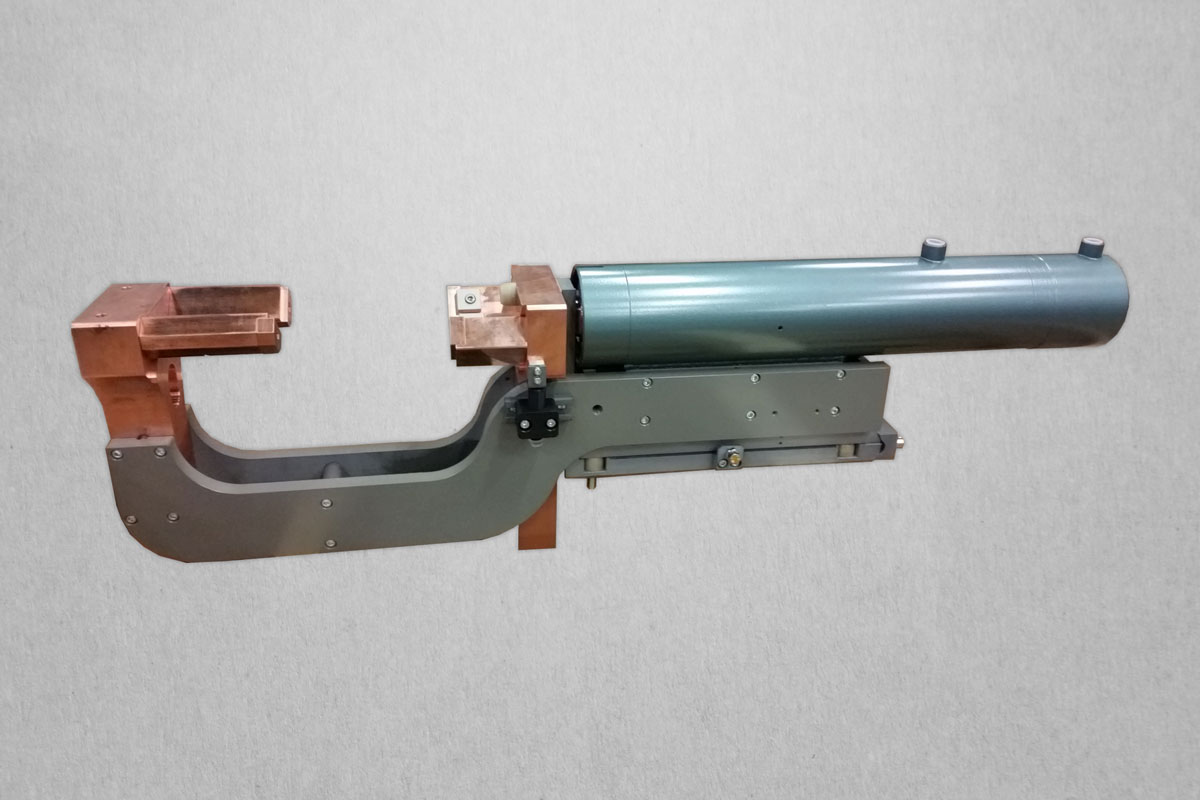

Welding Cylinder Equipment

The range includes equipment necessary for welding, replacement parts, mechanical stops and examples of models for limit controls. Our welding equipment range includes electrode holders for all cylinder types, electrode shanks, electrode caps, cooling tubes, secondary cables and jumpers. For cylinder maintenance we povide complete sets of replacement internal parts and seals. Inductive proximity switches, suitable for welding, are used for non-contact limit controls. In 90% of all applications, the type of proximity switch to be used has to be chosen with respect to the possible interference contours of the individual equipment. The proximity switch can be selected to individual works standard. All current models are available.